Department of

Knitwear Engineering (KE)

The long-standing trend of producing knitwear and sweaters in Bangladesh or, accordingly, of selling such knit goods abroad has resulted in knit design, knitting, knitwear manufacturing industries and their allied textile industries having an ever greater demand for graduates who possess the interfacial skills and competencies needed and, plus the required English language skills.

Bachelor of Science in Knitwear Engineering (abbreviated as B.Sc. in KE) degree to be offered by the Department of Knitwear Engineering at BUFT aims to produce students by making them capable of fulfilling that greater need to some extent.

The program has been designed with the philosophy and goal to provide individuals with an environment in which personal and professional aspirations can be fulfilled.The program allows students to foster their interest at an advanced level, by exploration and experimentation with new approaches to knit fabric design, manufacturing and garmenting, within a dynamic community, supported by professional staffing facilities, contemporary studio space and modern technical resources.

The program offered supports graduates all the way who wish to enhance and further develop as design and manufacturing specialists, within the field of knit fabric design, knit fabric manufacturing, and knitwear design & manufacturing engineering. In addition, the program also encourages students with demonstrated creative ability who wish to update or develop specialist skills. The program is structured keeping in view the present and future requirements of Bangladesh Knitting Industries.

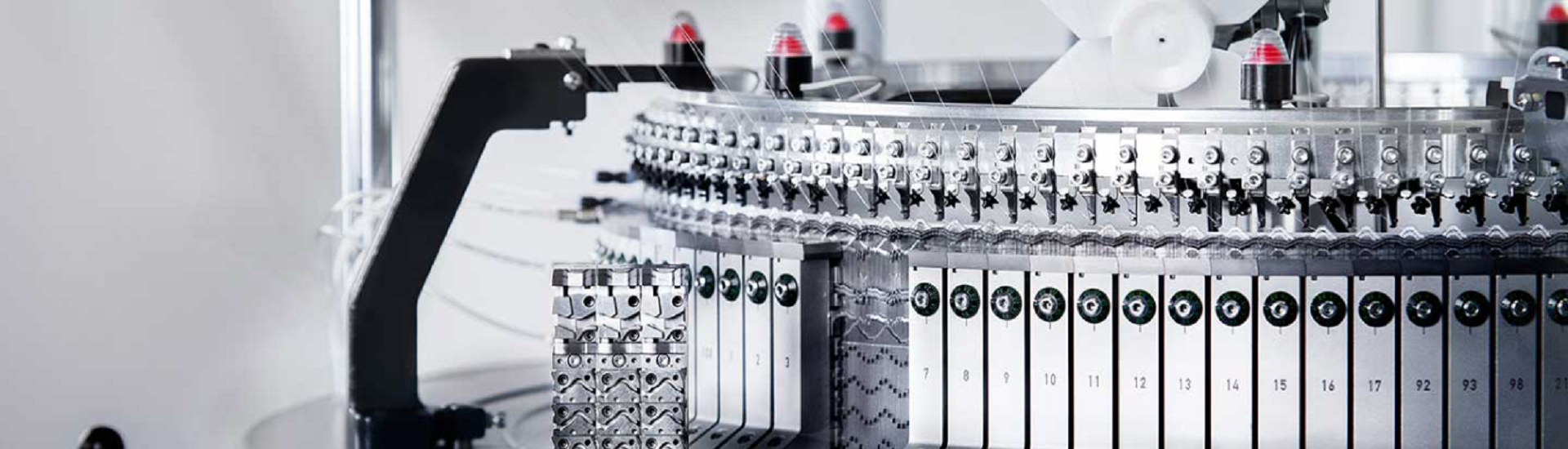

The ever-growing developments in yarn, texture, color, materials and composition have given an advantage to the technique of knitting to the extent that knitted fabrics have started replacing woven fabrics. The specialization requires the students to work on state-of-the-art machines like; computerized flatbed machines such as Shima Seiki, Universal and Stoll. The students are also exposed to the techniques and variants in the Circular Knitting manufacturing techniques, possible structure developments, surface treatment, processing and garmenting. Continuous interactions with the industries and visits to leading manufacturing units not only create an enriching learning environment for the students but also widen the horizons of their experience. The graduates are equipped with competent technical knowledge, thereby making them able to anticipate and address the concerns and issues of the emerging manufacturing principles.

Keeping this high demand of experts and skilled workforce in mind, BGMEA University of Fashion & Technology introduced a department, Department of Knitwear Engineering which offers an undergraduate program that develops in the students the ability to make intelligent business-like decisions with prudence.

Vision of the department

Mission Statement

M 1: The department seeks to produce globally competent graduates by providing in-depth knowledge to its students to educate them with the required competence to foster graduates intrinsic and extrinsic ideas taking full creative control over the design and creation of fabrics, garments products for fashion or interiors, process optimization, research, and product development. Additionally, achieve skills for effective communication, use of IT tools, quality & engineering management, and working in multi-disciplinary teams.

M 3: The department strives to impart education to our graduates with the required competence in the fields of knitting and knitwear manufacturing technology so that they can participate in the social, moral and economic developments of our nation.

M 4: The department would like to enable other academic disciplines partially and to expand horizons of the mechatronics engineering, economic growth, humanities and social sciences through academics, research and technological innovations in knitwear and their allied textile sectors.

Program of Study

The study of Bachelor of Science in Knitwear Engineering aims at producing graduates who specialize in the study area of knitting and knitwear with interfacial skills and competencies to meet the greater demand of knitwear and their allied textile sectors in Bangladesh. The program particularly focuses on the strengthening of key engineering functions of knit garment industries and understanding industrial engineering and ergonomic techniques. Emphasis is also given on production, planning, control and management practices applicable in the knitting and knit garment industries.

Students acquire comprehensive knowledge and insights in the field of knitting, knitwear manufacturing, relevant textile engineering, and gain important management and leadership qualifications. They also acquire cross-disciplinary problem-solving competencies and optimized language skills by attending courses and internships taught in English. The program additionally gives them an insight into various foreign mentalities, as well as intercultural knowledge. The curriculum is imparted through an interdisciplinary thrust for systematic learning.

The program is broken into a series of semesters. A total of eight academic semesters and a total of 145* credits. each comprising a set of subjects and learning experiences. The degree program is completed with an 8-week internship which the students do in a company, followed by the production of a dissertation, offered to the students to help them enhance their personality and develop interests in specific areas like values, personality development and character building, soft skills, communication skills, critical thinking skills, and professional ethics. The program trains young professionals for the highly diverse and versatile range of technical and business administration tasks in knitwear and their allied textile sectors in Bangladesh.. Studies also focus on specialized fields executive management positions in the fields of knit product design, knit product manufacturing and knit business management.

B. Sc. in KE (Code: 841)

The study of Bachelor of Science in Knitwear Engineering aims at producing graduates who specialize in the study area of knitting and knitwear with interfacial skills and competencies to meet the greater demand of knitwear and their allied textile sectors in Bangladesh. The program particularly focuses on the strengthening of key engineering functions of knit garment industries and understanding industrial engineering and ergonomic techniques. Emphasis is also given on production, planning, control and management practices applicable in the knitting and knit garment industries.

Profile of the program

- Name of the Degree: Bachelor of Science in Knitwear Engineering, abbreviated as B. Sc. in KE

- Language of Instruction: English

- Number of credits: 145

- Courses Start: Spring (January) & Fall (July) each year

- Standard time to attain the Degree: Four years (eight semesters, six months each)

- Minimum grade to attain the Degree: 2.50 in a scale of 4.00

Students acquire comprehensive knowledge and insights in the field of knitting, knitwear manufacturing, relevant textile engineering, and gain important management and leadership qualifications. They also acquire cross-disciplinary problem-solving competencies and optimized language skills by attending courses and internships taught in English. The program additionally gives them an insight into various foreign mentalities, as well as intercultural knowledge.

The program also focuses on strengthening of key engineering functions of knit garment industries and understanding of industrial engineering and ergonomic techniques. Emphasis is also given on production, planning, control and management practices applicable in the knitting and knit garment industries.